From each plastic screw or small part to the processor or memory, the iPhone is a puzzle made in most people, but less in the U.S.. How much text is in pieces and many countries are involved in producing the famous smartphone.

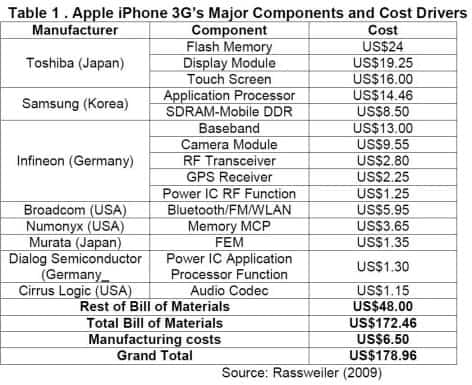

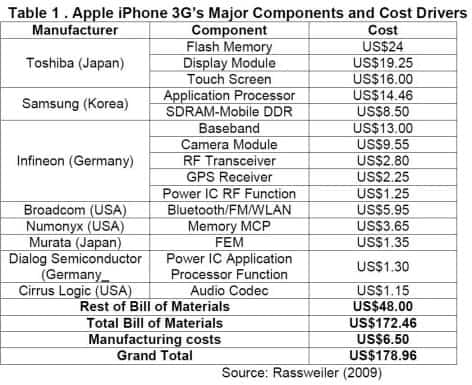

Flash memory costs $ 24 and the screen – 35. Both are produced in Japan. Processor and its associated components are Korean and manufacturing performance could however, costs only 23 dollars. GPS chip, camera and WiFi connections that provide parts and products are nemtesti $ 30. From a Japanese study that we learn and Bluetooth, audio components and the 3G connections are only made in the U.S. and parts worth 12 dollars. In addition, outside of these components, there are expenses or housing inside plastic, aluminum, software licenses and patents, all cost 48 dollars and come from Taiwan, Vietnam and many other states.

In total, the value of an iPhone is somewhere around 179 dollars and include 34% of Japanese products, 17% German, 13% Korean, American products and the remaining 6%, a combination of “magic” international origin parts!

How the iPhone Bury America in debts ?

Only in 2009 was responsible for a iPhone for $ 1.9 billion hole in the U.S. budget. Two academics have successfully demonstrated how a gadget to put cross finances of a nation: a product is “American” hard money imported from America. The problem is not new and they stay the outsourcing of production. That same “disease” suffered by any of today’s technological success. Every device, whether laptop or mp3 player, TV or air conditioner is a conglomerate assembled in a country where manpower is cheap and only designed in developed countries.

In a thesis univesitara two untie Japanese puzzle game that pulls in the U.S. economy every year, since 2007. Neal Detert Yuquig Xing and write in the document entitled “How to increase iPhone led the U.S. trade deficit from Asian countries” about the fact that only in 2009 the famous Apple product, an important call for 179 dollars U.S., was responsible for 0.8% of the U.S. trade imbalance in relations with China.

So the main companies supplying components for the iPhone are Toshiba, Samsung, Infineon, Broadcom, Numunyx, Murata, Dialog Semiconductor, Cirrius Logic, etc. All these are then sent by ship to Taiwan, the company Foxconn, where final assembly takes place. From here go to U.S. products and to the world.

Behind this apparent chaos, the effect of global production is beneficial for a company like Apple. That’s because all the companies involved in the process signed documents prevents them from directly competing product “American”.

Check Out These Too:

- The Rise of Cheap Iphone’s The Iphone, one of the world’s top of the line, best-selling smart phones in the market. Apple has created a way to combine cell phone, email, internet and other information…

- HTC One X Vs. Apple IPhone 5 - Is It ONLY About Image? We find out why the HTC One X when compared to the Apple iPhone 5 came out on top. When we look back to September 2012 we see very clearly…

- Iphone with GPS Will Soon Be Available Iphone with GPS Will Soon Be Available Iphones now have become a new trend for many people, especially for teenagers, students, and employees. It may happen because you can stay…

- IPod Touch 4th Generation Update: After got success with the iPod touch 4th generation, now apple gadget fans waiting for ipod touch 5th generation. There was a lot of ruckus and hullabaloo made over…

- How To Manage Memory On Your iPod Touch While your iPod Touch can do a lot of amazing things, it is still just a very compact device with limited amounts of resources. As such, launching plenty of apps…

- Apple White iPhone Will Be Available By The End of April It has already been 10 months since rumored white iPhone came into being that immediately thrilled iPhone users and other technology geeks. This rumor has also been reported in Bloomberg…

- iTalk Recorder Griffin Technology has built a solid reputation as a manufacturer of accessories for iPods and iPhones. This year, they made their first foray into developing a software for iPod Touch…

- Protect Your Apple iPhone with InvisibleSHIELD… Protect Your Apple iPhone with iPhone Screen Protector - AppleRepo, You Apple iPhone could be the best among all your gadget collections for years. The fact that it has become the…

- Apple to start using Taiwan Company to Produce Processors Apple has a lot of products on the market at the moment that are using some of the best processors around at the moment. For example, all of their Macbook…

- How to get a low cost iPhone 4s Apple’s iPhone 5 is expected to be released within the next few days and Apple are sure to have a lot of new tricks up their sleeves for the phone.…

- Expandable Memory and Storage of iPhone The Expandable memory of iPhone is DDR-SDRAM. It contains 1GB in which 16MB is reserved for the GPU. It has 8K blocks. There are four banks in the iPhone memory.…

- Best iPhone Photo Applications Best iPhone Photo Application - The iPhone is a new generation mobile phone from Apple Inc. It is one of the most popular phones in the world. The iPhone is…

- How to Increase the Battery Life of IPod Touch? For all those guys who are looking for some or the other way to increase the ipod battery life and backup time for their IPods here are few simple tricks:…

- Apple Mac Notebook Prices Mac notebooks are famous in the electronics market for its good quality, stylish look and efficient performance. Moreover another thing that everyone will notice is that the price of this…

- 3 Reasons to Buy IPhone 7S Reasons to Buy IPhone 7S in 2017 - AppleRepo.com, As the debate rages how inventive Apple iPhone 7S is, the real question remain is it worth your dollars? Its new…

- What is the Best Flashlight App for iPhone? Flashlight App for iPhone - AppleRepo.com, Apple is one of the largest electronics companies in the world, and one of its famous product icons is the iPhone and the iPad,…

- How to Turn On Led Flash on iPhone How to Turn On Led Flash on iPhone - In this article, I will show you how to turn on LED flash notification on iPhone 11, iPhone 11 Pro, and…

- iPhone 4S vs iPhone 4 Now that the iPhone 4S has been with us for a while it’s been long enough to weigh up whether or not it’s worthy upgrading to the newer Apple handset,…

- Apple release new Macbook Air As a lot of you will probably already know, every few months, Apple holds a keynote or press event in which they will often show off a variety of their…

- Apple is Partly Responsible for Killing Mobile Flash Today a major player with Adobe made it clear that Apple's resistance towards Flash on the iPhone helped significantly in killing the project. Up until this time Adobe repeatedly said…

- How Apple will revolutionize the education? Although our technology has invaded every aspect of life, learn how students and pupils remained unchanged. They now do not peel or textbooks, notebooks and pens, something that Apple is…

- Can You Use Bluetooth with the iPod Touch One of the most common questions about the iPod Touch is whether or not it has Bluetooth capabilities. Well, with the software update for the second generation iPod Touch, the…

- iPhone and iPad sales could be banned in Germany,… iPhone and iPad sales could be banned in Germany after Motorola's competitors have achieved a historic victory in the "patent war" that they carry with Apple. The case relates to…

- New iPod Touch faster than iPhone 3G Apple has been adapting its iPod since the music Wizard was launched and every time it came it had something different in it for the music freaks. The new iPod…

- IPod Touch Screen Protector for Maximum Protection You Want So what are you waiting for? Protect your Ipod Touch Now with Screen Protector! Apple iPod Touch has a superb 3.5 inch widescreen measurement. Apple iPod touch owners…

- Bluetooth Headphone for iPod Touch Are you Planning to buy a Bluetooth Headphone for your iPod Touch? Now you have the device, the iPod touch? Using your Apple iPod touch is more than you…

- iPhone 6 Release Date: A Call Out To Gadget Lovers iPhone 6 Release Date: A Call Out To Gadget Lovers Though there is still the much anticipated release of the iPhone 5, avid gadget collectors are already waiting and are…

- Apple iPhone 5 Could Arrive Late due to Overheating The next generation of the Apple iPhone is expected to be released by Apple shortly and there have been rumours that it will even be released as soon as this…

- Memory Trainer Pro iPhone App Review Memory Trainer Pro iphone app – is an exciting collection of games for iPhone/iPad designed by RaptLook.com to improve memorization skills of player's brain. What you can find inside of…

- How Does The Samsung Galaxy S4 Hold Up Against The… If you want the best of the best when it comes to mobile phones, and you're willing to pay the price, there are some incredible high end phones out there…